In plastic recycling systems, plastics shredder and plastics granulator are both used for size reduction—but they serve very different purposes. Choosing the right machine (or the right combination) can significantly improve efficiency, safety, and final material quality.

When building a plastic recycling line, choosing the right pelletizing system is essential for producing clean, uniform, and high-quality recycled pellets. Among all plastic pelletizing machines, Single Screw Pelletizers and Twin Screw Pelletizers remain the two most widely used technologies.

Amstar Machinery offers customized HDPE and PET sorting solutions, tailored to your plant layout and production goals. Turnkey systems maximize efficiency, improve purity, and ensure long-term reliability for modern recycling projects.

The Amstar SWHB800 plastic crusher handles bulky and flexible plastics with superior efficiency, anti-winding rotor design, and easy maintenance. Ideal for recycling car bumpers, chemical barrels, and films, it delivers higher output, lower downtime, and enhanced safety for modern recycling plants.

Learn how to safely disassemble bearings on centrifugal dryers. Step-by-step instructions, maintenance tips, and recommended spare parts help ensure long-term reliability, prevent downtime, and extend the lifespan of your drying system.

A plastic crusher (plastic granulator) is essential for recycling, converting waste plastics into uniform flakes for efficient washing, drying, and pelletizing. With the right machine and configuration, recyclers can improve output, reduce costs, and produce high-quality recycled pellets for a sustainable production cycle.

Amstar’s hot melting densifier transforms bulky EPS foam into high-density ingots, making foam recycling easier, cleaner, and more cost-effective. With a 1:50 compression ratio, it reduces waste volume, cuts handling costs, and turns low-value foam into valuable recycled material.

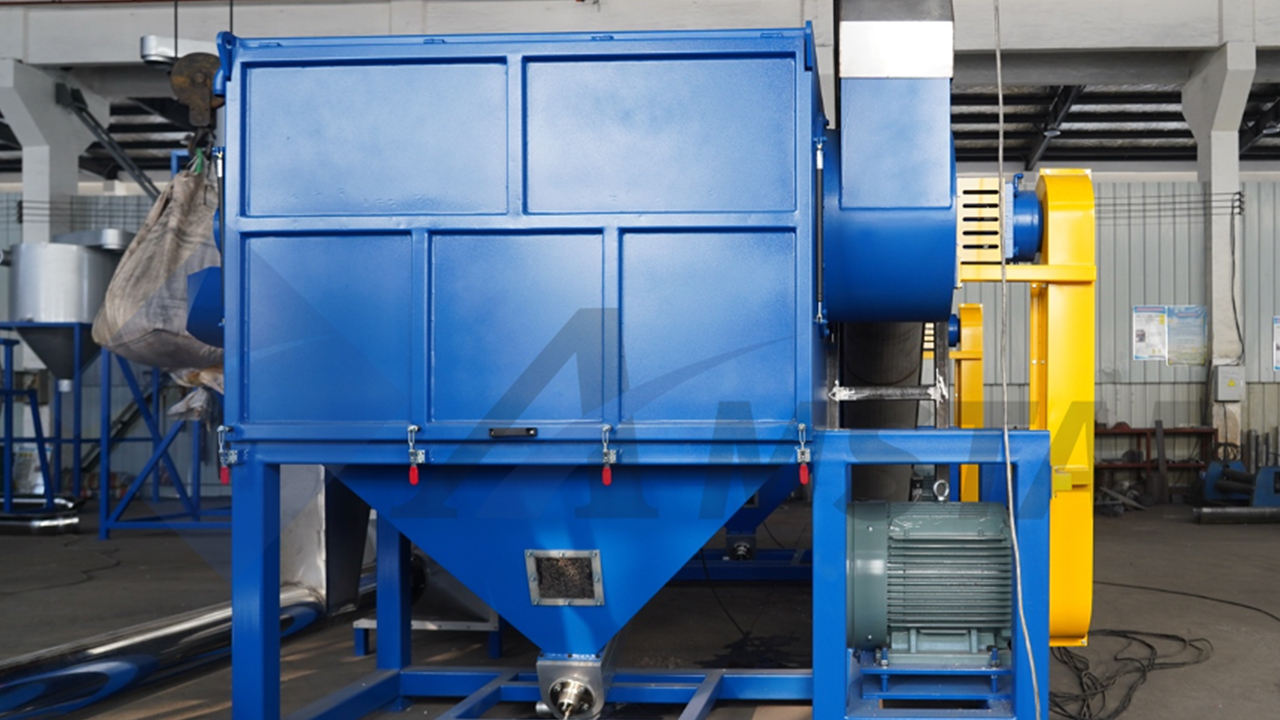

Amstar’s double shaft shredder delivers high-torque, heavy-duty performance—efficiently breaking down HDPE plastics, children’s safety seats, and bulky bins or tubes into clean, consistent output for streamlined recycling workflows.

Rubber shredders are engineered for tough tire and elastomer recycling, using low-speed, high-torque cutting to handle elastic materials and separate steel wire. Compared to single- and double-shaft designs, they offer cleaner, more controlled output for tire processing.

A high-speed centrifugal dryer (also known as a plastic dewatering machine) offers the most efficient solution — removing up to 95–98% of surface water within seconds, before the material enters a thermal dryer or extruder.