An upgraded version of our general purpose plastic granulators, these wet plastic granulator machines offer the same speed and efficiency for cutting plastic bottles, films, and rigids with an added twist. We have upgraded the rubber seals and materials to allow for water to be sprayed directly into the cutting chamber. There are major benefits of a wet granulation process that results in long-run savings for your recycling operation.

- The most obvious advantage of adding water to your granulation process is it partially cleans and loosen the dirt and contaminants from the recycling stream. This is a great way to pretreat the plastic for further cleaning with our high-speed friction washers.

- Water acts as lubrication for the fast spinning blades to reduce friction and heat buildup resulting in improved durability of the blades and machine as a whole. This greatly extends operation times before needing to sharpen the blades.

- Due to the dusty nature of plastic recycling streams, a wet granulation process offer a major benefit of lowering dust buildup in your plant.

WORKING PRINCIPLE

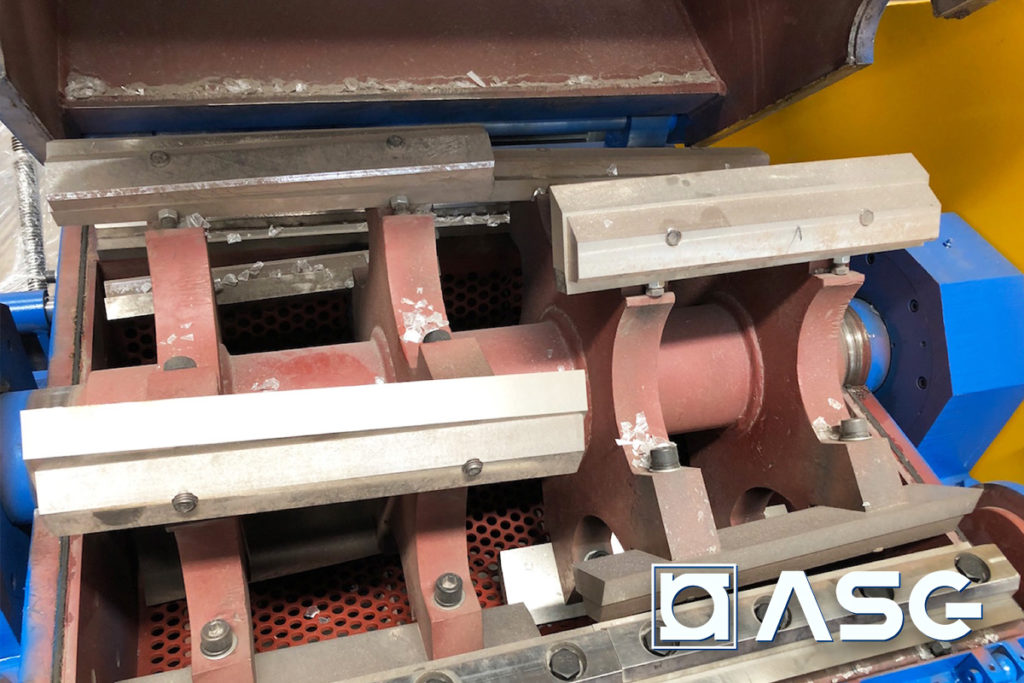

In terms of grinding, our wet plastic granulator machines are identical in structure to our general-purpose plastic granulators. At the core of this machine is an open rotor mounted with ultra durable D2 (equivalent to SDK11) high-carbon, high-chromium steel knives in either a double-scissor cut or v-shape array based on your requirements.

For purposes of cutting PET bottles and plastic films, we suggest using the v-shape arrangement. If the granulator is mainly used to cut rigid plastics, use the double-scissor cut arrangement.

As the rotor is spun at high speeds between 400-600 rpm, these extremely sharp rotor knives come in contact with stationary knives that are mounted within the cutting chamber.

A water line is added to the rear of this wet plastic granulator machine where water is sprayed onto the plastic as it is being cut. The plastic mixes within the cutting chamber as it is continuously cut and pre-washed until the pieces are small enough to pass through a screen filter.

Our standard screen filter size is between 10mm – 100mm but can be customized to your requirements.

TECHNICAL SPECIFICATIONS

| Model # | Rotor Diameter | Rotor Width | Rotating Speed | Approx. Output | Motor Power |

| SWHB600-W | ⌀450mm | 600mm | 400-600 rpm | 300 kg/h | 37KW |

| SWHB800-W | ⌀500mm | 800mm | 400-600 rpm | 600 kg/h | 45KW |

| SWHB1000-W | ⌀600mm | 1000mm | 400-600 rpm | 900 kg/h | 75KW |

| SWHB1200-W | ⌀700mm | 1200mm | 400-600 rpm | 1200 kg/h | 90KW |

*Larger, more powerful models available based on your request.

APPLICATIONS

Our wet granulator machines are an excellent choice for all sorts of plastic recycling operations including but not limited to grinding plastic bottles, buckets, films, and other small sized rigid plastics.

Although slightly more expensive compared to our general-purpose general granulator, a wet granulation process provides improved durability and reduced maintenance resulting in more long-term savings for your business.

PLASTIC GRANULATORS VS SHREDDER MACHINES

Although granulators and shredders are sometimes used as synonyms, they are in fact very different machines used for different purposes.

Plastic granulators are high-speed machines for cutting relatively smaller-sized plastics into flakes and fine regrinds. For example, plastic bottles, small buckets, and other rigid plastic products.

For large-sized, tough plastics such as plastic lumps and purge from the extrusion process, a single-shaft or double-shaft plastic shredder machines is more suitable. Plastic shredders are very adequate in cutting large, bulky materials into small pieces. Once the plastic pieces are small enough, they can be fed into the plastic granulators to produce regrinds or flakes.

ADDITIONAL IMAGES

WARRANTY

All plastic recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.