Our complete PET bottle washing line is an ideal solution for anyone looking to start or improve their plastic bottle recycling business. This fully automated, turnkey solution processes baled PET bottles into contaminant-free PET flakes. These plastic flakes can be sold for high prices to manufacturers of polyester staple fiber or can be pelletized into granules for use in manufacturing other PET products.

While our standard PET bottle washing lines are sufficient for most facilities, custom setups with additional machinery and increased capacity can be designed for your specific needs.

WORKING PRINCIPLE

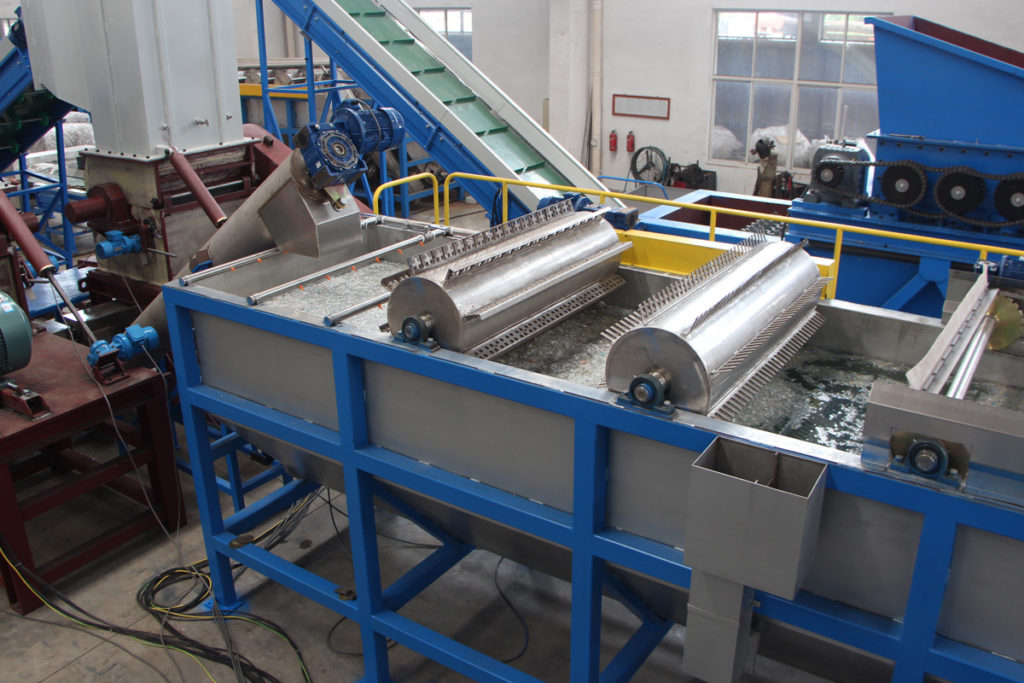

Our turnkey PET bottle washing line consists of a series of our plastic recycling machines connected using various types of conveyor systems.

Debaler Machine: The first step in our plastic bottle washing line is to break the compacted bales of PET bottles into a free flowing stream. Once the bales are “busted”, the bottles can move freely onto the next machine.

Trommel: An optional piece of equipment, the trommel is a slowing rotating tunnel lined with small holes. The holes are slightly smaller than the PET bottles so small pieces of contamination (such as glass, metals, rocks/dirt, paper, etc…) can fall through while the PET bottles move onto the next machine.

Wet Plastic Granulator: Sometimes referred to as a plastic crusher, our plastic granulator machine cuts the PET bottles into small flakes between 10-15mm in size. With water constantly spraying into the cutting chamber, this wet granulation process pre-treats and partially cleans the material before moving onto the next equipment.

Air Classifier: Air classification is a way to separate lighter materials from heavier ones. The main purpose of using the air classifier is to remove contaminations such as paper, cardboard, and plastic labels away from on PET flakes.

Sink / float Separation Tank: Using water as a medium, materials that float are separated from materials that sink. In the case of plastic bottle recycling, PET plastic will sink while plastic film (bottle labels) and PP/PE plastic (bottle caps) will float. A screw conveyor at the bottom of the sink float separation tank moves the PET plastic to the next piece of equipment.

Hot Washer System: Hot washed PET flakes are of higher value because this process dissolves glues (used to glue labels onto the bottles) and leftover beverages/foods that are difficult to remove in a cold wash process. Although you can just use water in the hot washer system, adding washing agents can added for better results.

Friction Washer: A efficient piece of cold water washing equipment, the high speed friction washer uses friction as a mechanical way to remove any hard to remove dirt and debris from the PET flakes.

Dewatering Machine: The first step in the drying process, our centrifugal dewatering machine uses centrifugal force to remove a large portion of water within the PET flakes before moving forward onto our thermal dryers.

Thermal Dryer: PET flakes are vacuumed out of the dewatering machine into the thermal dryer where it travels down a series of stainless steel tubes mixed with hot air. This process removes any remaining moisture by dehydration. An attached cyclone separator mixes the PET flakes with cool air preparing it for storage in the product silo.

Product Silo: A storage tank for the clean, dry PET flakes.

Pelletizer / Extruder: For the most part, PET flakes are used as is particularly in manufacturing polyester fibers. However, we do have customers requiring plastic pelletizing machines such as our single-screw extruder pelletizers and twin-screw extruder pelletizers.

TECHNICAL SPECIFICATIONS

| Input Capacity | 500 kg/h | 1000 kg/h | 1500 kg/h | 2000 kg/h | 3000 kg/h |

| Required Space [LxWxH] | 42mx10mx6m | 50mx15mx6m | 55mx16mx6m | 60mx18mx6m | 100mx20mx6m |

| Operators | 3-5 people | 6-8 people | 7-9 people | 8-10 people | 10-12 people |

| Installation Power | 150KW | 250KW | 370KW | 450KW | 750KW |

| Water Circulation (T/H) | 2 | 3 | 3 | 4 | 5 |

*Larger, more powerful models available based on your request.

HIGH QUALITY PET FLAKES

Our PET washing line produces high-quality PET flakes that are clean and contamination free. Below are typical benchmarks for PET flakes produced from this recycling line:

- Moisture: < 1-2%

- Bulk Density: < 0.3G/CM3

- Total Impurity: < 320ppm

- PVC Content: < 100ppm

- Metal Content: < 20ppm

- PE/PP Content: < 200ppm

- Particle Size: < 14-16mm

ADDITIONAL VIDEOS & IMAGES

WARRANTY & INSTALLATION

All recycling machinery comes with a limited warranty

We offer installation packages where our engineers travel to your facility to guide your through the installation process the. Routine maintenance teams and operations consultants can also be arranged to ensure your PET recycling plant runs smoothly year and year.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.