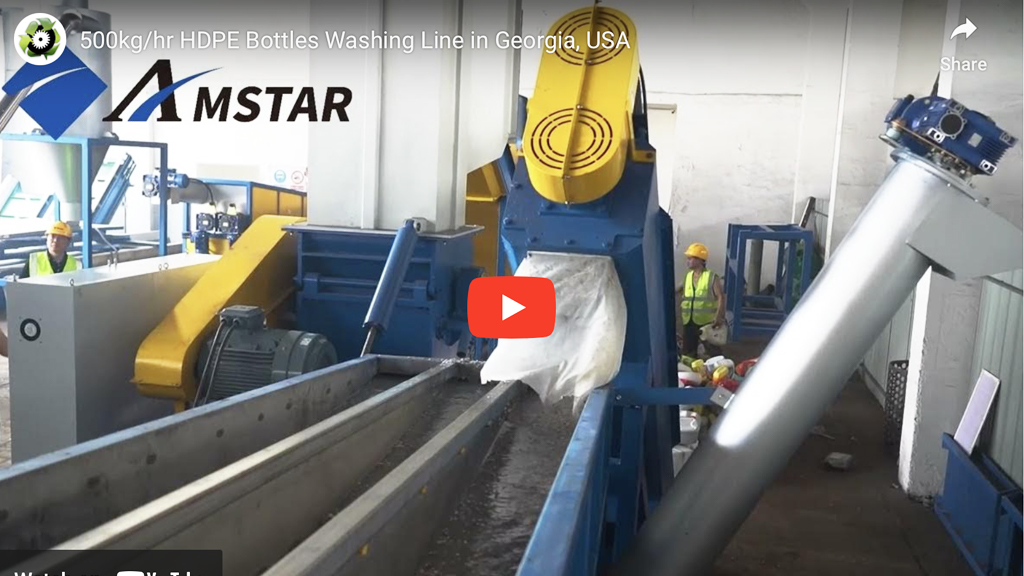

Welcome to our video on the specialized HDPE bottles crushing and washing line designed for our client in Georgia. This plastic recycling system, capable of processing 500 kg per hour, is tailored to handle HDPE bottles efficiently and effectively.

Discover the advanced features of our 2000kg/hr HDPE PP Rigid Plastic Crushing and Washing Line, located in Swadlincote, UK.

Here we're showcasing a trial run of our 2000kg/hr HDPE PP Rigid Plastic Crushing and Washing Line, all the way in Swadlincote, UK.

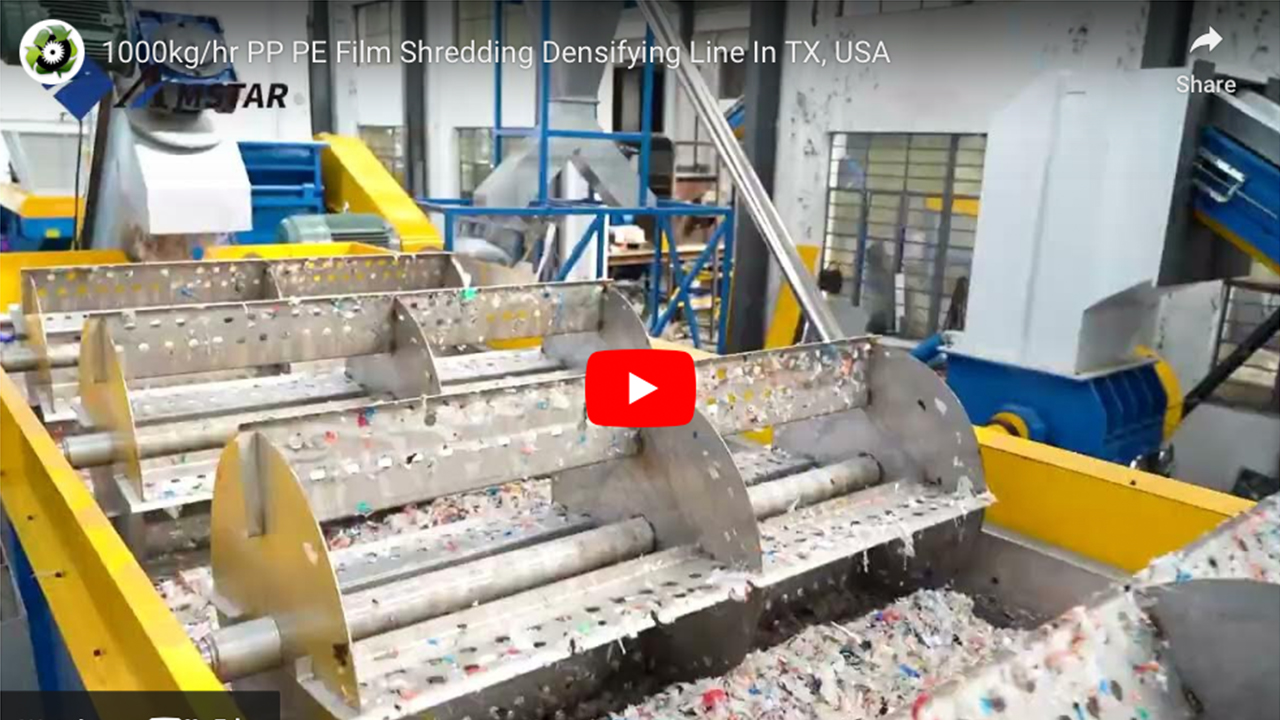

This is a trial run of our PP / PE film shredding and densifying line for a petroleum service corporation in Texas, USA.

This is a trial run of our 2500kg/hr rigid plastics washing plant for a returning customer in Charlotte, USA. We supplied a similar line to this customer in 2022.

Our complete PET bottle washing and recycling line is your processing large bales of PET bottles into contaminant-free PET flakes.

Whether you're working with PP, PE, or other types of plastic film, our complete plastic film washing line will fulfill your every need for recycling loose or baled plastic film into plastic pellets you can sell for healthy margins

Our PP PE film shredding densifying line is your complete solution for turning dirty bales of PP/PE films into densified product ready for chemical application or processing into plastic granules via pelletizing.

This is a trial run of our PP / PE film washing and densifying line for a customer in NY, USA. The final densified material will be used in a chemical recycling application.

The two-stage PP PE pelletizing system is used to process film regrinds from a washing plant. It consists of two sets of single screw extruders to insure the finished product is of high quality.