Our 1000 kg/hr HDPE Plastics Recycling Line is designed for processors who need a complete, high-efficiency solution from bale opening → shredding → crushing → washing → pelletizing.

This system delivers stable output, low energy consumption, and consistent pellet quality for bottle-to-bottle, bottle-to-film, or injection-grade applications.

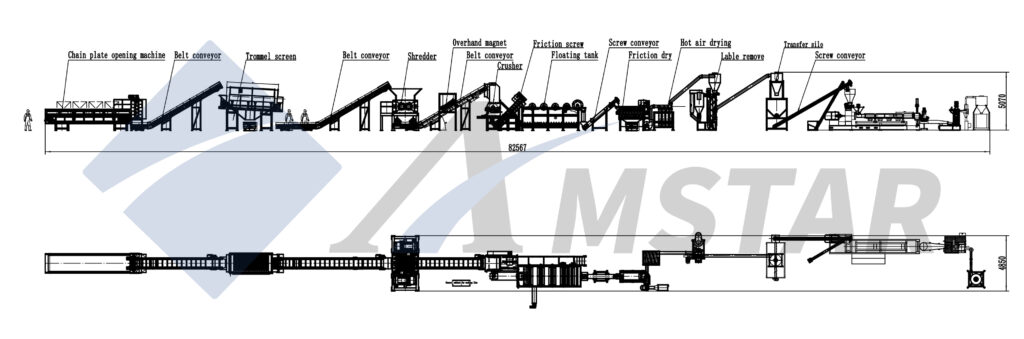

Process Flow & Line Configuration

Shredding & Washing Line

The shredding and washing section is designed to handle baled HDPE materials efficiently and prepare clean, dry flakes for pelletizing.

- Chain Conveyor (LBJ-1400)

Transfers baled HDPE materials into the debaling system.

- Debaler (PBJ-1000)

Breaks compacted bales into loose materials for stable downstream processing.

- Belt Conveyor (PS-1000)

Conveys loosened materials to the trommel.

- Trommel (GS-1500)

Removes sand, stones, and fine contaminants from incoming HDPE materials.

- Belt Conveyor with Magnetic Drum & Overhead Magnet (PS-1000)

Separates ferrous metals before shredding.

- Single Shaft Shredder (DSL-1500)

Performs primary size reduction of HDPE bottles, drums, and rigid containers.

- Belt Conveyor with Magnetic Drum & Overhead Magnet (PSL-800)

Further metal removal and material transfer to the wet crushing stage.

- Wet Crusher (SWHB1000)

Reduces material into uniform flakes while performing initial washing.

- Friction Screw (LX-500)

High-speed friction washing to remove labels, dirt, and surface contaminants.

- Floating Tank with Discharge Auger (QXC1500)

Sink-float separation to remove heavy impurities and non-HDPE materials.

- Centrifugal Dryer with Round Separator (TS1000)

Mechanical dewatering to significantly reduce moisture content.

- Hot Air Dryer (RSJ)

Further drying to ensure flakes meet pelletizing moisture requirements.

- Label Separator (PM-1000)

Separates residual labels and light contaminants from HDPE flakes.

- Transit Silo

Buffer storage for clean and dry HDPE flakes before pelletizing.

- Electric Control System

Centralized control for the shredding and washing line.

Pelletizing Line Configuration

The pelletizing section converts clean HDPE flakes into uniform pellets with stable output.

- Belt Conveyor

Feeds dried HDPE flakes from the transit silo into the pelletizing system.

- Feeder

Ensures consistent and controlled material feeding into the extruder.

- Single Screw Extruder (180 × 28)

Primary melting and plasticizing of HDPE material.

- Hydraulic Screen Changer

Removes fine contaminants and ensures melt cleanliness.

- Single Screw Extruder (200 × 10)

Secondary extrusion for pressure stabilization and improved pellet quality.

- Hydraulic Screen Changer

Final melt filtration before pelletizing.

- Water Ring Cutting System

Continuous pellet cutting with uniform pellet size.

- Storage Hopper

Collects finished HDPE pellets for packaging or storage.

- Control Cabinet

Independent control system for the pelletizing line.

Key Features

- Stable 1000 kg/hr output for HDPE bottles, jerrycans, barrels, and similar rigid plastics

- Modular design for easy layout adjustment

- High washing efficiency, ensuring low-contamination flakes

- Optional de-labeler, metal detector, steam washer, melt filter, die-face cutter

Typical Output Quality

- Flake size: 12–16 mm

- Final moisture: ≤ 2–3%

- Pellet MFI stability: Suitable for injection molding and extrusion

Get a Complete Proposal

If you’re looking for a reliable 1000 kg/hr HDPE recycling line for your factory, we can customize the layout, washing configuration, and pelletizing solution based on your actual material and budget.

Inquiries

To get the latest prices and lead times, send us a message using the form below.