Amstar’s hot melting densifier transforms bulky EPS foam into high-density ingots, making foam recycling easier, cleaner, and more cost-effective. With a 1:50 compression ratio, it reduces waste volume, cuts handling costs, and turns low-value foam into valuable recycled material.

Amstar’s double shaft shredder delivers high-torque, heavy-duty performance—efficiently breaking down HDPE plastics, children’s safety seats, and bulky bins or tubes into clean, consistent output for streamlined recycling workflows.

Rubber shredders are engineered for tough tire and elastomer recycling, using low-speed, high-torque cutting to handle elastic materials and separate steel wire. Compared to single- and double-shaft designs, they offer cleaner, more controlled output for tire processing.

A high-speed centrifugal dryer (also known as a plastic dewatering machine) offers the most efficient solution — removing up to 95–98% of surface water within seconds, before the material enters a thermal dryer or extruder.

Amstar provides pelletizing lines for different types of plastics. This guide shows which line fits which material—single-screw, two-stage single-screw, or twin-screw—along with key points like mixing, degassing, and filtration.

It all starts with the rubber belt conveyor, which feeds the plastic waste smoothly into the star of the show—the DSJ 2000 single-shaft shredder with a moveable hopper.

This video showcases our custom-built 1000 kg/h PP/PE plastic film shredding and densifying line, tailored specifically for a corporate client based in Florida, USA.

Here we're showcasing a trial run of our 2000kg/hr HDPE PP Rigid Plastic Crushing and Washing Line, all the way in Swadlincote, UK.

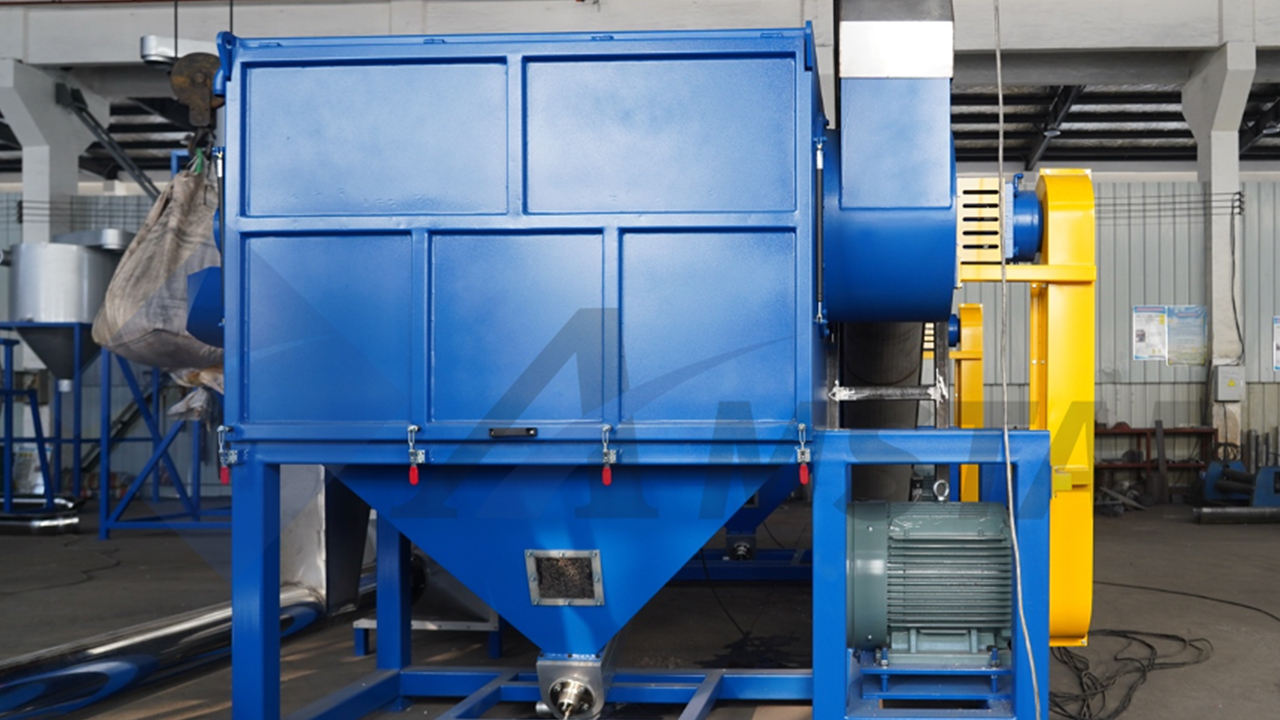

The Roller / Disc Screen is a high-performance, heavy-duty screening solution specifically designed for plastic recycling lines. Featuring multiple rotating shafts equipped with cast-steel or coated discs, this equipment excels at precise size-based separation, making it a vital pre-sorting unit for modern PET, HDPE, PP, and mixed plastic recycling systems.

Featuring our Laser Filter Automatic Screen Changing and Slag Discharge System, this line delivers uniform, high-quality pellets even from highly contaminated input materials.