1. Types of Industrial Shredders

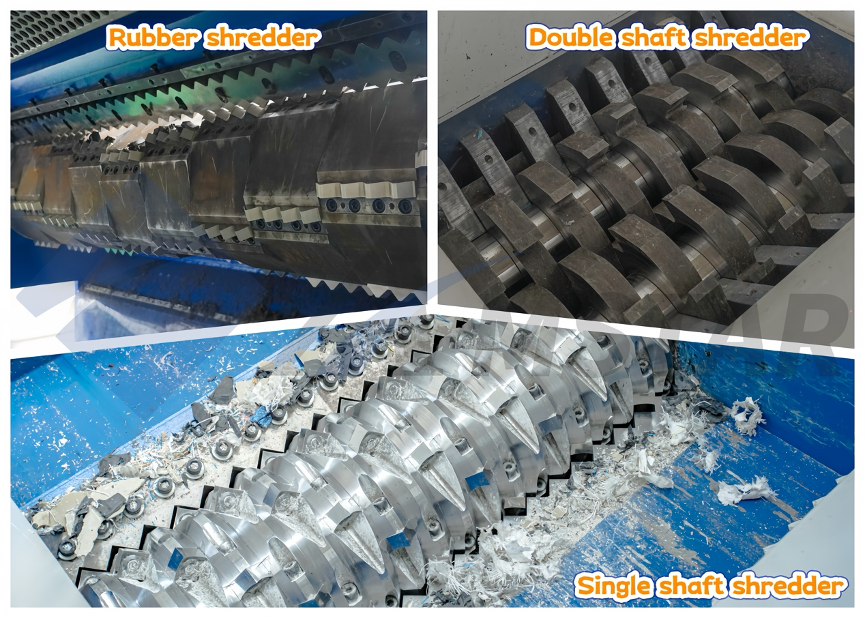

Rubber Shredder (Tire Shredder)

A rubber shredder is specially designed for tires, rubber blocks, and elastomer materials.

It runs at low speed and high torque, using wear-resistant alloy blades to tear, shear, and cut rubber into small chips.

Rubber shredders are ideal for tire recycling lines where steel wire needs to be separated.

They can process whole tires, truck tires, or precut rubber strips.

Typical output size: 30–80 mm, depending on screen configuration.

Single-Shaft Shredder

A single-shaft shredder features one rotor equipped with cutting knives that rotate against a fixed counter-knife and screen.

It’s ideal for plastic film, lumps, purgings, or wood waste where uniform size control is needed.

The hydraulic pusher ensures continuous and even feeding.

Advantages: clean cut, low noise, controllable output.

Output size: 10–40 mm, depending on screen holes.

Double-Shaft Shredder

Also known as a twin-shaft shredder, this type uses two counter-rotating shafts with hooked blades.

It’s built for heavy-duty applications — bulky materials like metal drums, pallets, plastic barrels, or tires.

Because it has no screen, the output size is irregular but the throughput is high.

Advantages: strong torque, low speed, low maintenance.

Output size: 50–300 mm (rough shredding).

2. Quick Comparison Table

| Type | Working Principle | Ideal Materials | Output Size | Key Features |

| Rubber Shredder | Low-speed, high-torque shear cutting | Tires, rubber blocks | 30–80 mm | Designed for elasticity & steel wire separation |

| Single-Shaft Shredder | Rotor + counter-knife + screen | Film, lumps, plastics, wood | 10–40 mm | Uniform output, hydraulic pusher, quiet |

| Double-Shaft Shredder | Dual counter-rotating shafts | Drums, bulky waste, tires | 50–300 mm | High throughput, coarse shredding |

3. How to Choose the Right Shredder

| Application | Recommended Shredder |

| Whole or truck tires | Rubber/Tire Shredder |

| Hard plastics, purgings, or pipes | Single-Shaft Shredder |

| Bulky solid waste or mixed material | Double-Shaft Shredder |

| Fine size reduction before pelletizing | Granulator |

Tips for Selection:

- Choose rubber shredders when processing elastic materials or tires with wire rings.

- Use single-shaft for plastics where consistent flake size is required.

- Double-shaft fits coarse shredding before secondary processing.

- Add a granulator if your end goal is fine flakes for extrusion or pelletizing.

4. Why Choose Amstar Machinery

- Proven expertise: Over 20 years of experience in recycling systems for PET, HDPE, PP, and rubbermaterials.

- Reliable performance: Machines built with Siemens or WEG motors, NSK/SKF bearings, and precision-cut blades ensure stable operation.

- Custom solutions: From single-shaft to rubber shredders, Amstar designs complete recycling lines tailored to material type and capacity.

- Global installation base: Systems successfully running in Europe, North America, Africa, and Asia.

- After-sales support: 24-hour technical response, spare parts, and online service for long-term operation.

INQUIRIES

To learn more about this product, please send us a message using the form below: