When building a plastic recycling line, choosing the right pelletizing system is essential for producing clean, uniform, and high-quality recycled pellets. Among all plastic pelletizing machines, Single Screw Pelletizers and Twin Screw Pelletizers remain the two most widely used technologies.

This article provides a clear comparison of both systems to help recyclers select the most suitable solution for their materials and production goals.

1. Overview of the Two Pelletizing Systems

Single Screw Pelletizer

A single-screw extruder uses one rotating screw to convey, melt, and pressurize plastic.

Key Features

- Can be combined with water-ring cutting, strand cutting, or underwater pelletizing

- Simple mechanical structure, easy to maintain

- Stable output with uniform heating

- Energy-efficient, suitable for clean and consistent materials

Twin Screw Pelletizer

A twin-screw extruder uses two intermeshing screws to create stronger mixing, shearing, and dispersing effects.

Key Features

- Excellent mixing and dispersing

- Strong shear force for fiber-filled or additive-heavy materials

- Self-cleaning effect reduces residue inside the barrel

2. Applications Based on Material Type

Choose a Single Screw Pelletizer if you process:

- PE/PP film flakes

- HDPE/PP rigid regrind

- General recycled plastics with stable quality

- High-output pelletizing lines for standard materials

Best for recyclers who prioritize stability, low operating cost, and easy maintenance.

Choose a Twin Screw Pelletizer if you process:

- Plastics with additives, fillers, or reinforcements

- PC-ABS, PA, PP-GF, engineering plastics

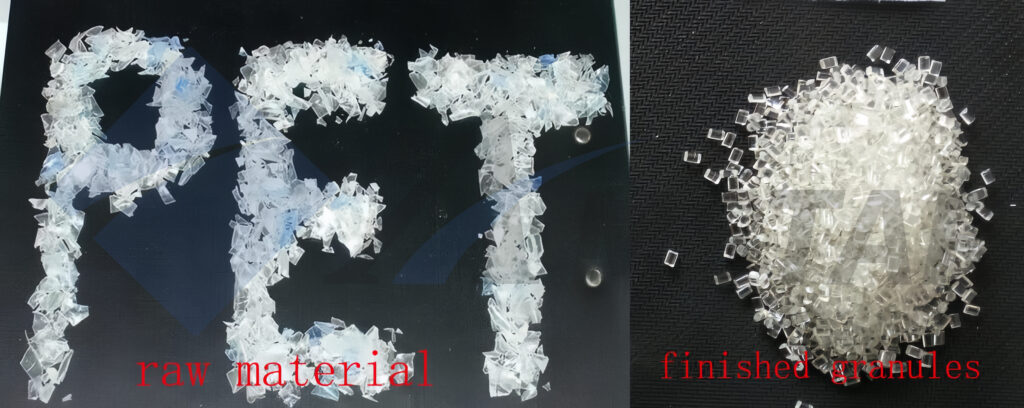

- PET Bottle flakes

- Material blending, coloring, or compounding

- Heat-sensitive or high-precision formulations

Best for advanced compounding and high-value recycled pellet applications.

3. Summary Table: Which One Should You Choose?

| Question | Best Choice |

| Need strong mixing & compounding? | Twin Screw Pelletizer |

| Processing standard PE/PP regrind? | Single Screw |

| Processing additives or glass-fiber materials? | Twin Screw |

| Need the highest pellet uniformity? | Twin Screw |

| Want maximum energy efficiency? | Single Screw |

4. Final Recommendation

Both pelletizing systems play important roles in plastic recycling:

- The Single Screw Pelletizer is ideal for mainstream recycling applications—high output, low maintenance, and stable quality.

- The Twin Screw Pelletizer is the best choice for complex formulations, engineering materials, and high-value recycled pellets.

Many customers combine both systems in a two-stage pelletizing setup, using a twin screw for mixing and a single screw for high-pressure extrusion—achieving the best performance for difficult materials.

Inquiries

To learn more about this product, please send us a message using the form below: