With the rapid growth of PET bottle recycling worldwide, stable output, high purity, and energy efficiency have become key requirements for modern recycling plants.

The 1000KG/H PET Bottle Washing Line is designed to deliver consistent washing quality while maintaining low water and energy consumption. Combined with a compact pelletizing system, this line transforms waste PET bottles into high-quality recycled pellets ready for reuse in manufacturing.

System Overview

This complete recycling solution includes two main sections:

- PET Bottle Washing Line – for cleaning, separating, and drying PET flakes

- Pelletizing Line – for converting clean flakes into uniform pellets

The system is ideal for:

- Beverage bottle recycling

- Food-grade PET processing (with optional upgrades)

- Medium-capacity recycling plants (1000 kg/h)

Bales of mixed post consumer bags and film from municipal curbside residential collection stacked in rows waiting to be marketed and processed in to usable resin

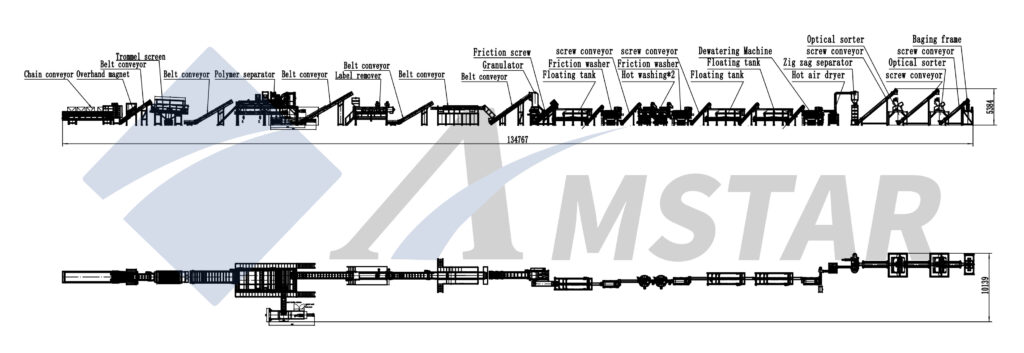

PET Bottle Washing Line

The washing line is designed for efficient removal of labels, caps, dirt, glue, and contaminants. The process combines mechanical washing, flotation separation, and thermal cleaning to ensure high-purity output.

Equipment Configuration (Simplified)

| No. | Equipment Name | Model |

| 1 | Chain Conveyor | LBSS-1400 |

| 2 | Debaler | KB-1000 |

| 3 | Belt Conveyor (with Magnetic Drum) | PSL-800 |

| 4 | Label Remover | TB-800 |

| 5 | Sorting Conveyor | PS-800 |

| 6 | Belt Conveyor | PS-800 |

| 7 | Wet Crusher | SWHB1200 |

| 8 | Friction Screw | MCX-400 |

| 9 | Floating Tank (1st) | QXC1500 |

| 10 | Hot Washer | ZG1700 |

| 11 | Friction Screw | MCX-400 |

| 12 | Floating Tank (2nd) | QXC1500 |

| 13 | High-Speed Dryer | TS1000 |

| 14 | Hot Air Dryer | RSJ |

| 15 | Label Separator | PMFX-00 |

| 16 | Finished Product Silo | LC |

| 17 | Electrical Control System | — |

Key Process Highlights

- Efficient Label Removal

Mechanical friction + airflow separation ensures clean PET flakes.

- Hot Washing Technology

Removes oil, glue, and organic residues effectively.

- High Dehydration Efficiency

Combination of centrifugal and hot air drying reduces final moisture content.

- Stable Output Quality

Suitable for pelletizing or direct reuse.

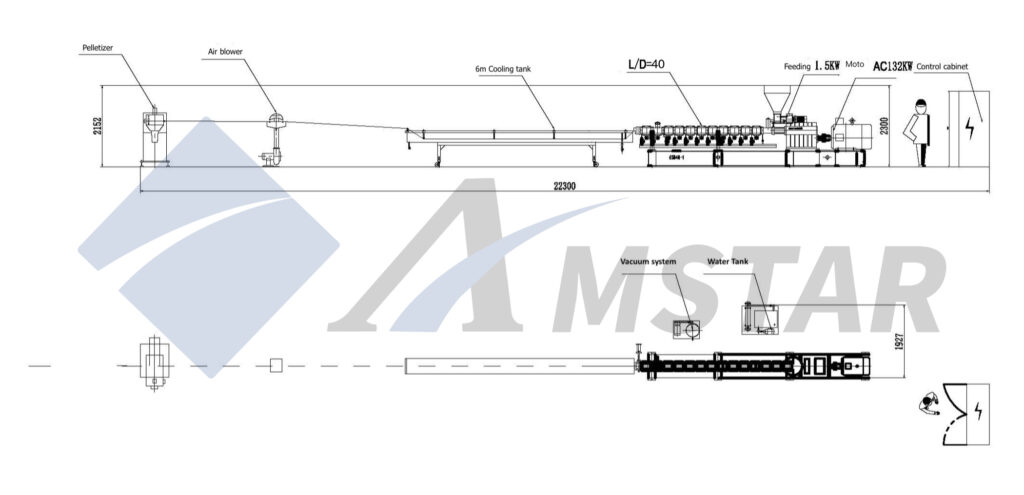

PET Pelletizing Line

The pelletizing system converts washed PET flakes into uniform pellets, suitable for extrusion, injection molding, or sheet production.

Pelletizing Line Configuration

| No. | Equipment Name | Model |

| 1 | Screw Feeding Conveyor | DTC1000 |

| 2 | Double Screw Extruder | SJ75 |

| 3 | Hydraulic Screen Changer | YH |

| 4 | Cooling Tank | LQSC350 |

| 5 | Dryer | CGJ500 |

| 6 | Pelletizer | QL-500 |

| 7 | Vibrator | ZDS-500 |

| 8 | Air Blower | SFJ160 |

| 9 | Finished Product Storage | GLC-4 |

| 10 | Control Cabinet | — |

Pelletizing Advantages

- Stable extrusion pressure and temperature control

- Uniform pellet size and smooth surface

- Low energy consumption

- Easy operation and maintenance

Why Choose This 1000KG/H PET Recycling Line?

✔ Stable and continuous operation

✔ Modular design for easy expansion

✔ Optimized for energy and water saving

✔ Suitable for bottle-to-bottle or fiber-grade recycling

✔ Proven configuration with reliable components

Final Notes

This 1000 KG/H PET Bottle Washing and Pelletizing Line offers a balance between capacity, efficiency, and cost, making it a reliable solution for many recycling operations

However, we understand that 1000 kg/h may not always be the ideal capacity for every project. Depending on your material type, space availability, energy requirements, and future expansion plans, a customized solution may deliver better long-term value.

If you are unsure whether this configuration fits your production goals, feel free to contact us. Our technical team will be glad to evaluate your requirements and recommend a more suitable layout, capacity, or system configuration tailored to your recycling needs.

Inquiries

To learn more about this product, please send us a message using the form below: