This 1000KG/H PP PE Film Washing Pelletizing Line is designed for efficient recycling of post-industrial and post-consumer plastic films such as PP woven bags, PE agricultural film, LDPE packaging film, and stretch film.

Optimized specifically for light, flexible film materials, this system integrates shredding, washing, dewatering, densifying, and pelletizing into one continuous production line.

It is an ideal solution for recycling plants seeking stable output, low moisture content, and high-qualityrecycled pellets suitable for extrusion or injection molding applications.

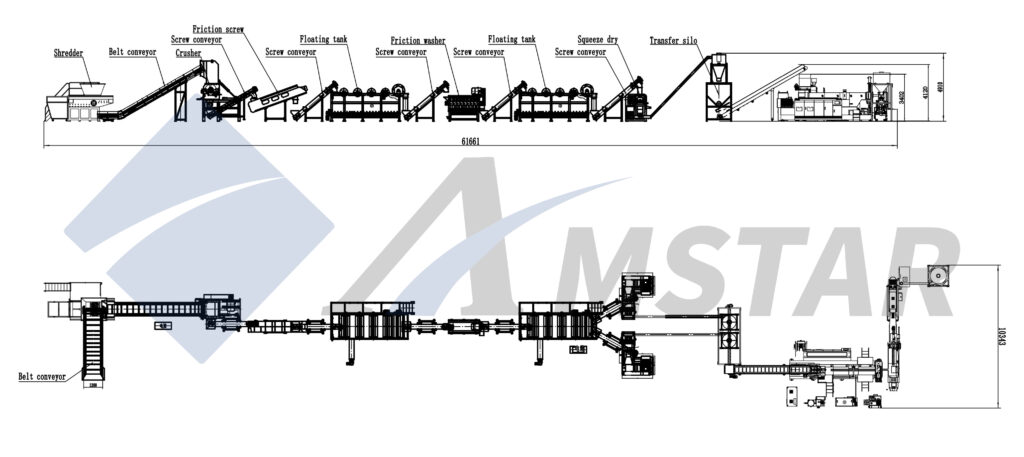

System Overview

The complete line consists of two main sections:

- PP PE Film Shredding & Washing Line – for size reduction, deep cleaning, and moisture removal

- Pelletizing Line – for melt filtration, extrusion, and pellet production

Designed Capacity: 1000 kg/h

Applicable Materials: PP / LDPE / LLDPE / HDPE film

Final Product: Clean, uniform plastic pellets

1. PP PE Film Shredding & Washing Line

This section focuses on removing dirt, sand, organic contamination, and residual moisture while maintaining material integrity.

Equipment Configuration

| No. | Equipment Name | Model | Function |

| 1 | Rubber Belt Conveyor | PSL-1600 | Uniform feeding of film material |

| 2 | Single Shaft Shredder | DSL-1600 | Heavy-duty size reduction |

| 3 | Belt Conveyor (Magnetic) | PS-1000 | Metal removal & transfer |

| 4 | Wet Granulator | SWHB-1200 | Cutting + pre-washing |

| 5 | Screw Conveyor | LX-356 | Material transfer |

| 6 | Friction Screw | LX-630 | Surface dirt removal |

| 7 | Floating Tank (1st) | QXC-1700 | Separation of contaminants |

| 8 | Friction Washer | HXJB-950 | Intensive washing |

| 9 | Floating Tank (2nd) | QXC-1700 | Final cleaning & separation |

| 10 | Screw Conveyors | LX-356 | Continuous transport |

| 11 | Squeezer (Dewatering) | JGJ-320 | Moisture reduction & densifying |

| 12 | Transit Silo | — | Buffer storage |

| 13 | Electrical Control System | — | Centralized control |

Key Washing Advantages

- Multi-stage washing for high cleanliness

- Floating tanks remove sand, labels, and heavy impurities

- High-speed friction washing improves surface purity

- Squeezer reduces moisture content to below 3–5%

- Optimized water and energy consumption

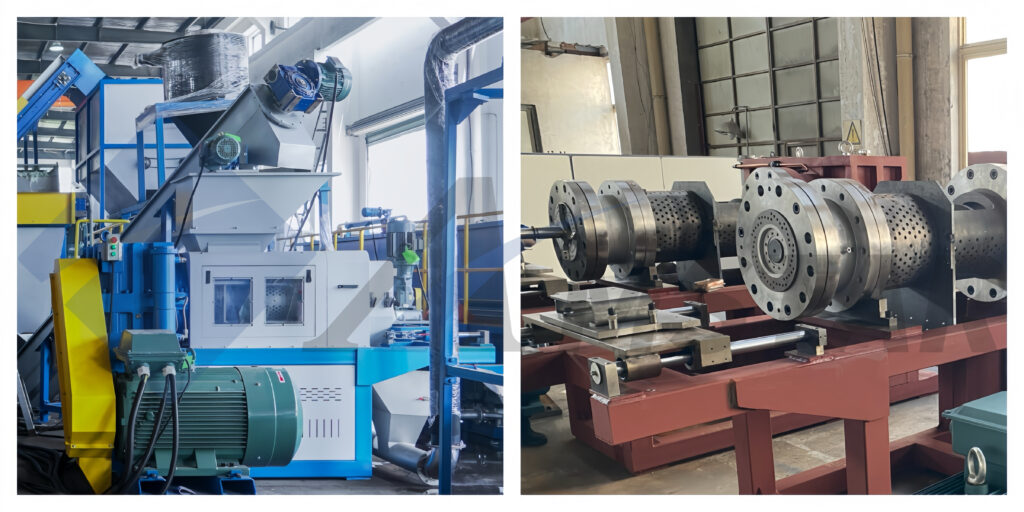

2. PP PE Film Pelletizing Line

After washing and densifying, the clean film flakes are converted into high-quality pellets through stable extrusion and filtration.

Pelletizing Line Configuration

| No. | Equipment Name | Model | Key Features |

| 1 | Feeding Conveyor | — | Controlled material feeding |

| 2 | Single Screw Extruder | SJ180/28 | High torque, stable melting |

| 3 | Hydraulic Screen Changer | — | Continuous filtration |

| 4 | Secondary Extruder | SJ200/10 | Pressure stabilization |

| 5 | Screen Changing System | — | Fast screen change (<2s) |

| 6 | Water Ring Pelletizer | — | Uniform pellet cutting |

| 7 | Centrifugal Dryer | — | Pellet dewatering |

| 8 | Storage Hopper | — | Finished pellet storage |

| 9 | Control Cabinet | — | Temperature & speed control |

Why Choose Amstar?

- Over 20 years of plastic recycling machinery experience

- Proven installations worldwide

- Customized layouts based on plant conditions

- Reliable after-sales service and technical support

Final Notes

This 1000KG/H PP PE Film Washing Pelletizing Line offers an excellent balance of capacity, efficiency, and pellet quality, making it suitable for medium to large-scale recycling projects.

If your raw material condition, contamination level, or plant layout differs, our engineering team cancustomize the configuration to ensure optimal long-term performance.

Inquiries

To get the latest prices and lead times, send us a message using the form below.