What Are Eddy Current Separators?

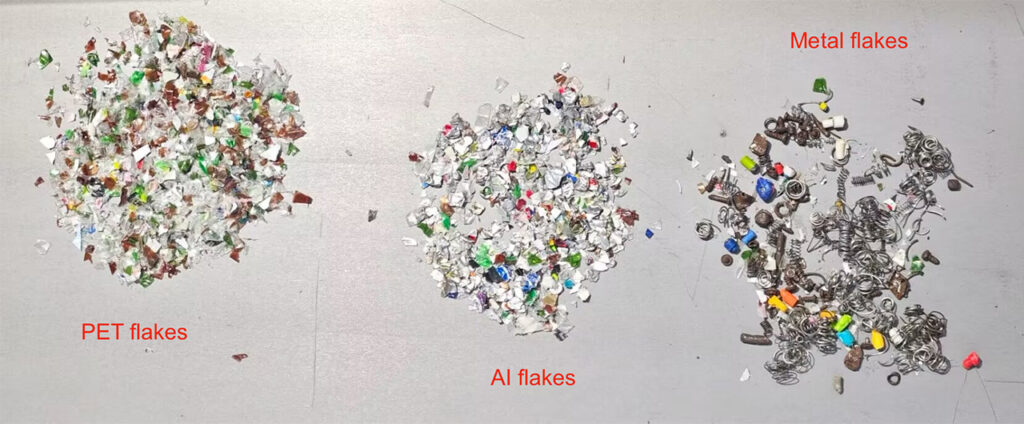

Eddy Current Separators (ECS) are advanced magnetic separation machines designed to remove non-ferrous metals such as aluminum and copper from PET recycling streams. Using electromagnetic induction, ECS efficiently separates metals based on their conductivity, enabling recyclers to recover valuable materials and achieve exceptional levels of material purity. These machines play a critical role in the PET recycling industry, enhancing the value of recycled PET flakes.

The Importance of Eddy Current Separators in PET Recycling

Eddy Current Separators are indispensable in addressing metal contamination, a key challenge in PET recycling. Their precision and efficiency ensure clean, high-value recycled PET materials. Here’s how they contribute to PET recycling processes:

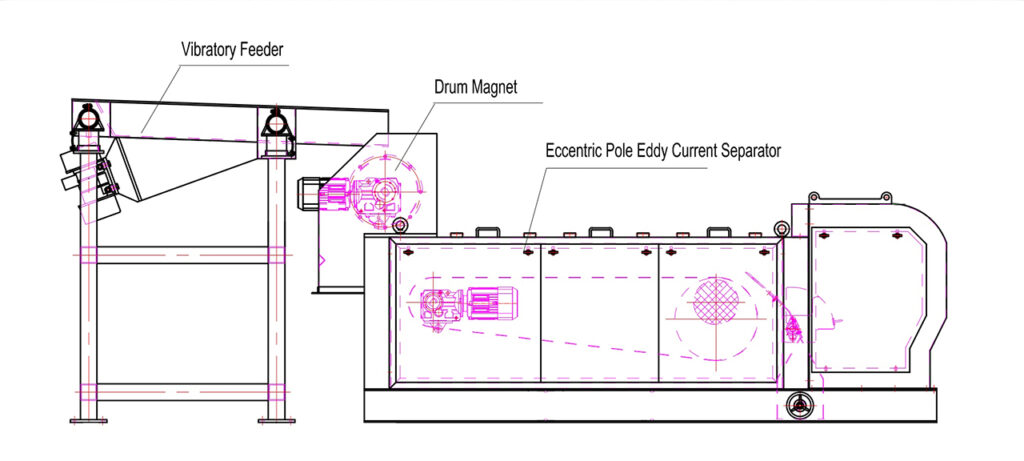

- PET Bottle Recycling: Magnetic separators and eddy current systems work together to remove contaminants. First, de-ironing equipment eliminates ferrous materials such as iron caps and debris. Then, high-frequency eccentric Eddy Current Separators effectively remove non-ferrous metals like aluminum caps and tabs, ensuring a cleaner output.

- PET Flake Processing: PET flakes often contain weakly magnetic stainless steel and non-ferrous metals. High-strength magnetic belts (10,000 Gauss) target weakly magnetic contaminants like stainless steel springs, while concentric Eddy Current Separators isolate aluminum and copper particles, delivering superior-quality recycled PET flakes.

How Do Eddy Current Separators Work?

Eddy Current Separators operate based on electromagnetic induction principles. The process involves:

- Feeding: Mixed material is placed onto a conveyor belt.

- Magnetic Rotor Action: A high-speed magnetic rotor generates eddy currents in conductive non-ferrous metals.

- Separation: The eddy currents repel metals, directing them into a separate bin, while non-metallic materials are collected in another bin.

- Enhanced Precision: The eccentric design ensures accurate separation of aluminum flakes as small as 2mm, achieving a metal removal rate of over 99%.

Key Equipment for PET Recycling

Amstar provides a range of tailored solutions for PET recycling to meet diverse material and purity requirements:

- Magnetic Separators: Efficiently remove ferrous contaminants like iron caps and fine debris.

- High-Strength Magnetic Belts (10,000 Gauss): Effectively target weakly magnetic contaminants such as stainless steel springs.

- Eccentric Eddy Current Separators: Precisely separate non-ferrous metals, including aluminum and copper, ensuring high-purity PET materials.

- Metal Detectors: Add an extra layer of quality control by identifying and removing residual metal contaminants.

Why Choose Amstar?

Amstar’s quality-assured equipment has been exported to over 50 countries and is trusted by recyclers worldwide. Known for its expertise in the PET recycling industry, Amstar provides customized equipment and innovative solutions that help clients maximize efficiency and achieve outstanding results. Collaborating with clients across Europe, Canada, the United States, and other regions, Amstar has established itself as a global leader in magnetic separation technology for PET recycling.

Conclusion

Eddy Current Separators are essential tools in modern PET recycling, ensuring the effective removal of non-ferrous metals and enhancing the quality of recycled materials. With Amstar’s proven expertise and tailored solutions, recyclers can transform PET waste into valuable resources, driving sustainability and innovation in the recycling industry.

For expert advice or more information about Amstar’s PET recycling solutions, contact our team today. Together, we can create a cleaner, more sustainable future.