Amstar introduces a reliable, space-saving solution for recycling bulky EPS materials with our EPS Hot Melting Machinery series. These machines transform foam waste into dense ingots, reducing volume by up to 90%, easing storage and transportation, and enabling eco-friendly reuse.

PRODUCT MODELS & SPECIFICATIONS

| Model | AM-EH 100 | AM-EH 200 | AM-EH 400 |

| Capacity | 40-50 kg/h | 100–120 kg/h | 180–200 kg/h |

| Screw Dia. | φ138 mm | φ197 mm | φ250 mm |

| Heating Power | 3 kW | 10 kW (3 zones) | 14 kW (3 zones) |

| Main Motor | 7.5 kW | 15 kW | 22 kW |

| Crusher Motor | 2.2 kW | 2.2 kW × 2 | 2.2 kW × 4 |

| Weight | 800 kg | 1400 kg | 1800 kg |

WORKING PRINCIPLE

Each EPS melter features:

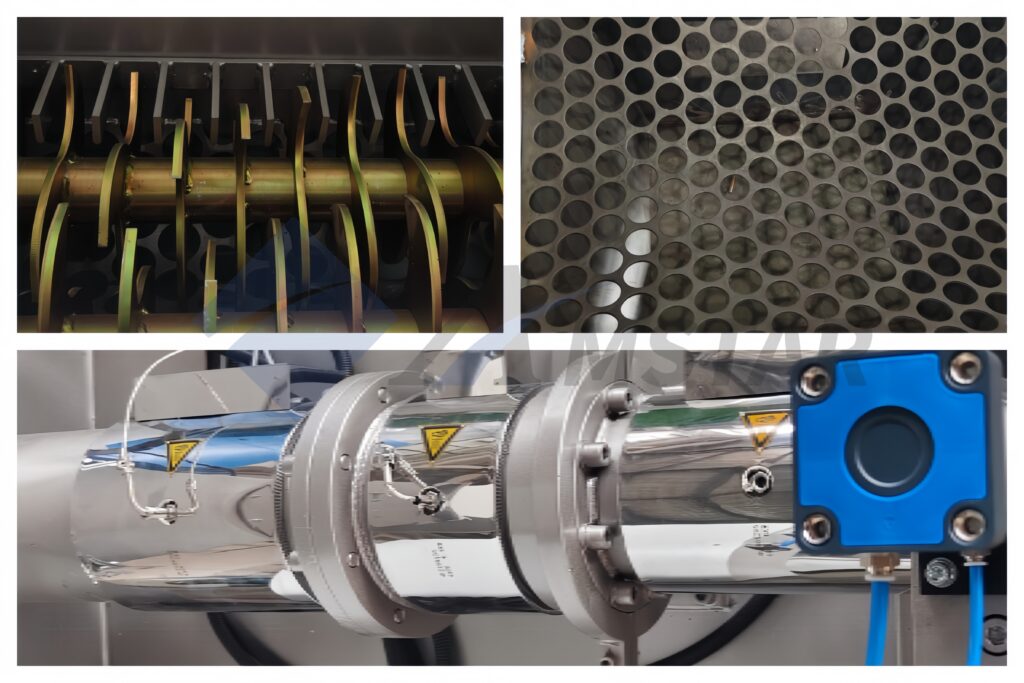

- Multi-shaft Crushing Blades: Breaks foam into small pieces.

- Rotary Screw Feeding: Transports material into a heating barrel.

- Thermal Compression: Melts EPS into semi-liquid form.

- Hydraulic Cutting System: Shapes material into dense, uniform blocks.

The process significantly reduces waste volume and produces high-density EPS ingots for reprocessing.

APPLICATION SCENARIOS

| Model | Suggested Use Environment |

| AM-EH 100 | Small retail stores, seafood counters, schools |

| AM-EH 200 | Medium-sized recycling stations, supermarkets |

| AM-EH 400 | Industrial-grade recyclers, municipal centers |

ENVIRONMENTAL BENEFITS

- Volume reduction of foam waste: up to 90%

- No water pollution or toxic emissions

- Contributes to circular economy and green manufacturing

- Low operational cost, high ROI

WARRANTY

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.