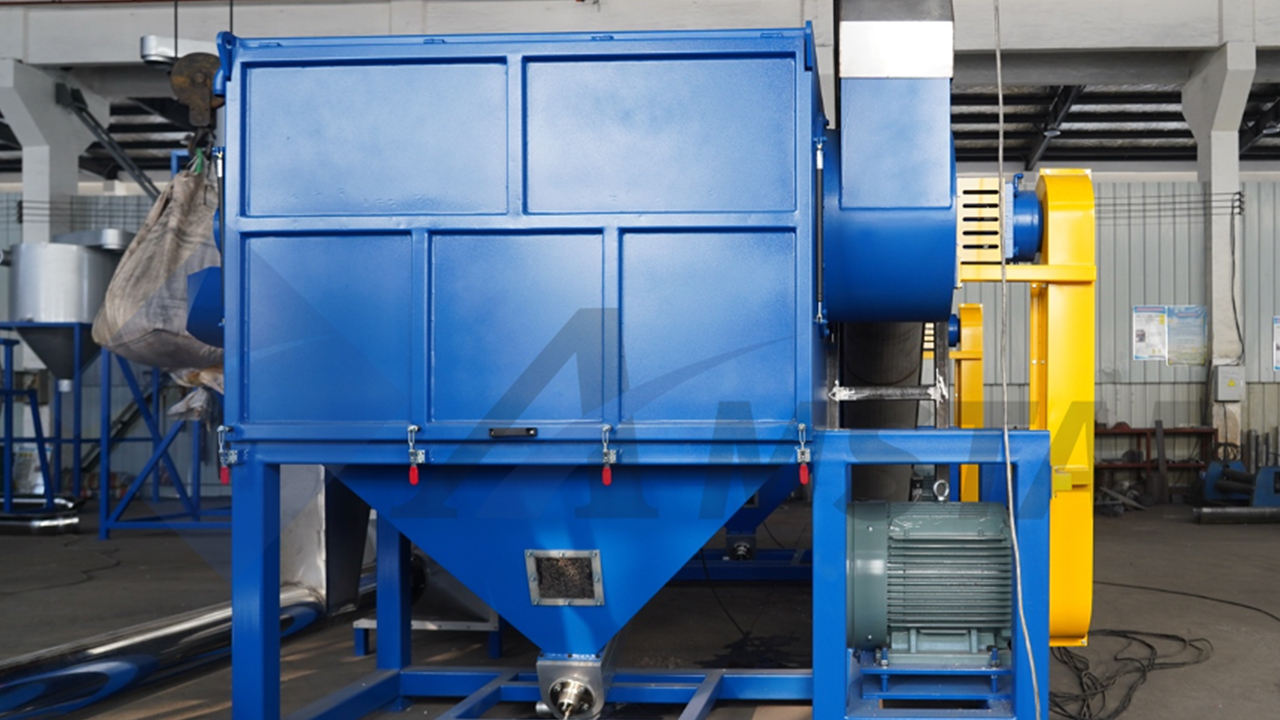

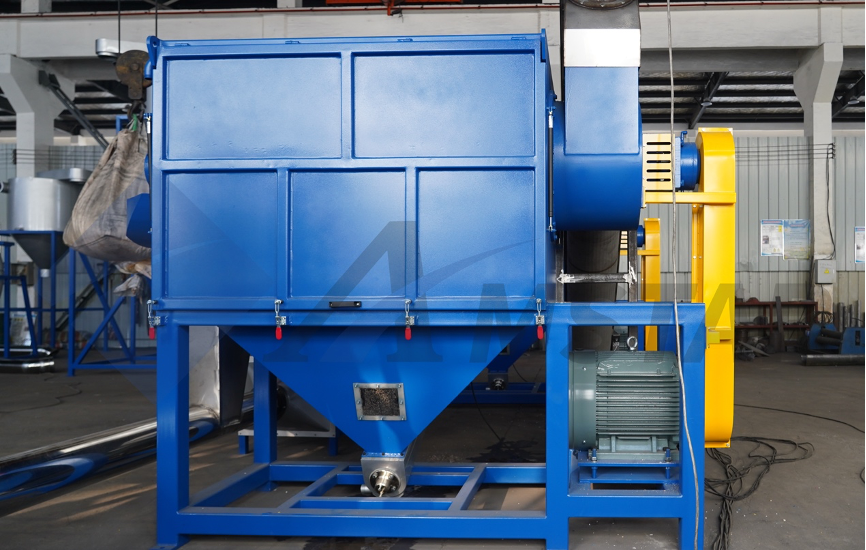

Efficient Moisture Removal for Flakes, Films & Pellets

When it comes to plastic recycling, moisture is the biggest challenge after washing.

Wet flakes or pellets can cause blockages, poor extrusion, or uneven pelletizing.

A high-speed centrifugal dryer (also known as a plastic dewatering machine) offers the most efficient solution — removing up to 95–98% of surface water within seconds, before the material enters a thermal dryer or extruder.

How the Centrifugal Dryer Works

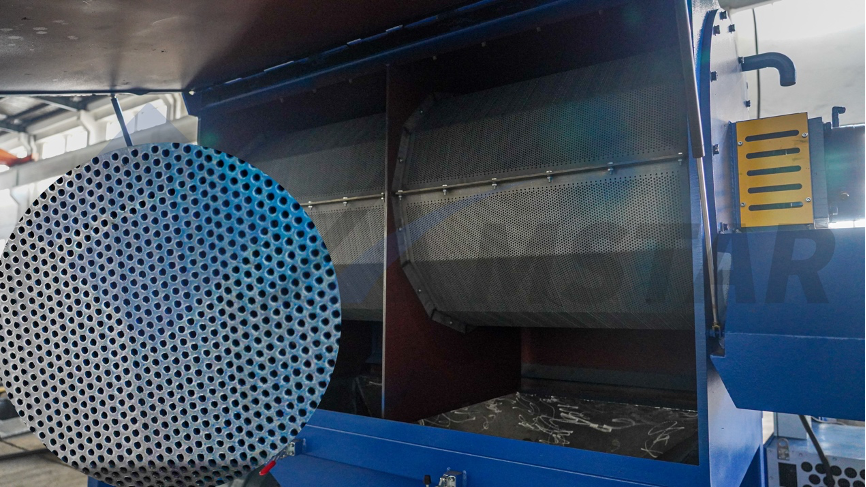

| Step | Process | Description |

| 1. Feeding | Wet flakes enter through a hopper or screw conveyor. | Material is evenly distributed into the spinning chamber. |

| 2. Spinning & Separation | High-speed rotation (up to 1,200 rpm). | Centrifugal force drives water through perforated screens. |

| 3. Discharge & Collection | Dry flakes exit from the top outlet. | Water drains away through the bottom channel and can be recycled. |

Result: Clean, dry flakes — ready for thermal drying, extrusion, or pelletizing.

Applications in Plastic Recycling / Reprocessing

Centrifugal dryers are widely used in plastics recycling and pelletizing because they offer fast dewatering with low thermal stress. Typical use cases include:

- Washing line after cleaning: After sink-float, friction washing, or hot washing stages, wet flakes can be dried by centrifugation before entering dryers or extruders.

- Pelletizing lines: Immediately after underwater pelletizer or cut-strand extruder, melt-cut pellets may carry water; a centrifugal dryer helps reduce surface moisture before further drying or storage.

- Flakes / PET bottle recycling: Removing physical water from PET flakes or mixed plastic flakes.

- Film / sheet recycling: For washed film / sheet pieces, centrifugal drying can reduce water without applying heat, reducing chance of sticking or distortion.

- Mixed plastic streams: When different plastic types are processed together, centrifugal drying is a non-thermal method less likely to degrade sensitive polymers.

- High-throughput lines: Because centrifugal dryers can process high volumes per hour (depending on size, rotor speed), they are suitable for industrial-scale recycling plants.

Advantages of Using a Centrifugal Dryer

Compared with traditional thermal drying methods, centrifugal dryers offer multiple operational and environmental benefits:

- ✅ Energy-saving: Uses mechanical energy instead of heat, reducing power consumption by up to 50%.

- ✅ Fast drying: Achieves 90–95% water removal in seconds.

- ✅ Low temperature: Protects heat-sensitive plastics from deformation.

- ✅ Compact footprint: Ideal for modular washing lines.

- ✅ Low maintenance: Fewer moving parts and minimal dust generation.

- ✅ Environmentally friendly: Recycles water, lowers carbon footprint.

These advantages make centrifugal dryers the preferred choice for PET bottle flakes, HDPE containers, PP woven bags, film scraps, and pelletized plastics.

Limitations / Challenges

- Not suitable for extremely fine powders (very small particles may pass through screens or not effectively dewater)

- Material carryover / losses: small granules may be lost if screen design is poor

- Vibration & mechanical stress: high rotational speeds demand precise balancing and structural rigidity

- Maintenance: screens can clog, bearings wear, sealing challenges

- Initial cost: well-built designs with robust parts may have higher capex

- Residual moisture floor: may not reduce moisture to as low as full thermal dryers in some cases

Why Choose Amstar Machinery

With over 20 years of experience in plastic recycling machinery manufacturing, Amstar Machinery is recognized for engineering efficient, durable, and fully integrated recycling systems.

Here’s why thousands of recyclers worldwide choose Amstar:

- Proven expertise: Over two decades of hands-on experience in PET, HDPE, and PP recycling solutions.

- Complete systems: From washing lines and friction washers to centrifugal dryers and pelletizing lines.

- Quality components: Siemens / WEG motors, NSK / SKF bearings, heavy-duty stainless steel construction.

- Precision manufacturing: Designed for high efficiency, reliability, and low vibration.

- 24-hour global support: Fast response and comprehensive after-sales service.

Conclusion

A centrifugal dryer is not just a drying unit — it’s the key to a clean, stable, and efficient recycling process.

By combining mechanical speed with smart engineering, Amstar’s dryers deliver high output, low energy use, and consistent results that keep your recycling line running smoothly every day.

Contact us today for a customized solution built for your specific materials and capacity.

👉 Explore More:

- High Speed Centrifugal Dryer — Fast, Efficient Drying for Plastic Recycling

- Centrifugal dryer for rapid drying for plastic recycling facilities In Washington, USA

- High-Speed Centrifugal Dryer – A Efficient Drying Solution

INQUIRIES

To learn more about this product, please send us a message using the form below: