Built for Tough Contaminants. Engineered for Purity.

Amstar’s Laser Filter System is designed to address one of the most critical challenges in plastic recycling: the efficient removal of solid industrial contaminants such as wood chips, paper fibers, stones, metal flakes, and other non-melting residues.

Whether handling post-consumer waste, agricultural film, or rigid packaging, the Amstar Laser Filter ensures stable filtration, high slag discharge efficiency, and minimal material loss—even with the dirtiest input materials.

Key Advantages at a Glance

| Feature | Description |

| Targeted Impurity Removal | Specially optimized for non-melting industrial solids like wood, paper, and stone. |

| Two-Stage Filtration | Integrated coarse + fine filtering in one step — ideal for heavily contaminated materials. |

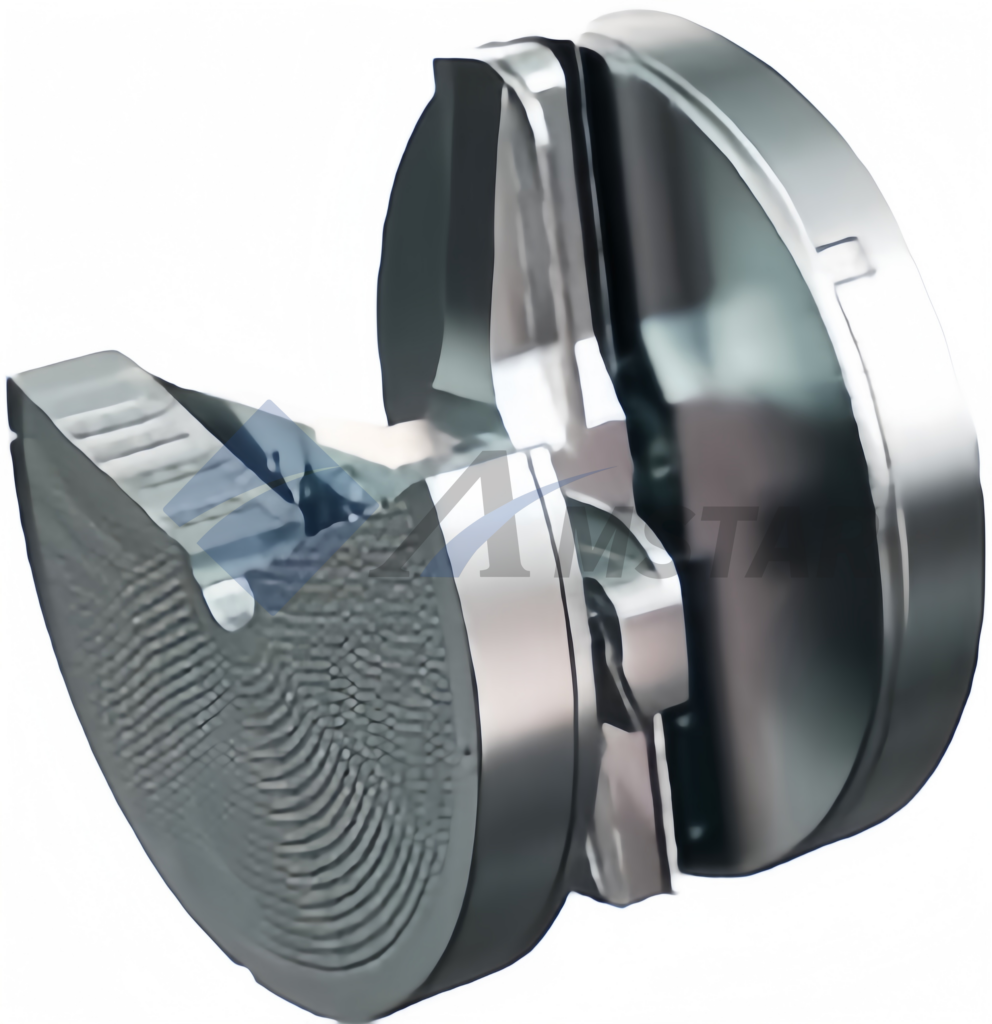

| Self-Cleaning Disc System | Laser-drilled disc filter with continuous or manual/automatic cleaning modes. |

| Pressure Monitoring | Equipped with real-time pressure sensors to regulate filter cleaning and avoid clogging. |

| Low Waste | Efficient slag removal reduces polymer loss during continuous operation. |

Working Principle

The Amstar Laser Filter employs a rotating disc system featuring laser-drilled micro-holes. As the melt flows across the filter surface:

- Coarse filtration captures larger contaminants like paper and wood.

- Fine filtration ensures downstream equipment receives high-purity melt.

- Slag removal is triggered by pressure thresholds or cleaning cycles, either automatically or via manual control.

This results in continuous, non-stop filtration — no production halt, no manual mesh changing.

Technical Specifications – Microfilt Disc Filter Series

| Model | Disc Diameter (mm) | Filtration Area (cm²) | Capacity (kg/h) |

| AMS-400 | Ø400 | 1100 | 200–300 |

| AMS-500 | Ø400 | 1700 | 400–500 |

| AML-400 | Ø400×2 | 1100×2 | 600–800 |

| AML-500 | Ø500×2 | 1700×2 | 1000–1500 |

Mesh Options: 60 / 70 / 80 / 100 / 120 / 130 / 140 / 150

Micron Range: 250μm – 106μm

Why Amstar Laser Filter?

✅ Reliable under pressure – Stable performance even in high-contaminant streams

✅ Fast & efficient cleaning – Disc rotation and pressure-triggered auto-purge

✅ Reduced downtime – No mesh replacement required

✅ Integrated into complete Amstar recycling lines – from washing to extrusionTechnical Specifications – Microfilt Disc Filter Series

Application Scenarios

• Post-consumer rigid plastic recycling

• Agricultural film with sand, wood, or fiber

• Industrial waste film or woven bags

• HDPE/LDPE film pellets with high impurity content

• Recyclers needing to upgrade filtration for higher-quality pellets

Comparison Chart

• Traditional Screen Changer vs Amstar Laser Filter (Pressure stability / Waste / Downtime)

| Feature | Traditional Screen Changer | Amstar Laser Filter System |

| Cleaning Mode | Manual screen replacement | Self-cleaning (auto/manual adjustable) |

| Operation Mode | Intermittent (requires downtime) | Continuous operation |

| Pressure Stability | Fluctuates during clogging | Stable, real-time pressure monitoring |

| Material Waste | High during filter change | Minimal due to efficient slag discharge |

| Filter Precision Options | Limited mesh range | 250–106 μm (60–150 mesh) available |

| Maintenance Frequency | High | Low |

| Best For | Lightly contaminated melt | Highly contaminated industrial melt |

Ready to Upgrade Your Filtration?

Whether you need a stand-alone filter or a complete recycling line, Amstar’s engineering team will help you customize the right solution for your application.

INQUIRIES

To learn more about this product, please send us a message using the form below: