A plastic crusher, also known as a plastic granulator, is a key size-reduction machine used in plastic recycling lines. Its primary function is to crush waste plastics into uniform flakes that can be washed, dried, and re-processed into high-quality recycled pellets. Whether processing PET bottles, HDPE containers, plastic films, pipes, injection scraps, or lumps, a plastic crusher is the first essential step that determines the efficiency, output, and final quality of a recycling system.

Today, plastic waste reduction and circular manufacturing are becoming global priorities. For recyclers, choosing a reliable crusher with stable capacity, consistent flake size, and durable cutting components can significantly improve line performance and reduce operational costs. The following sections explain how a plastic crusher works, where it is used, how to select the right configuration, and what affects its investment cost.

1. What Is a Plastic Crusher / Plastic Granulator?

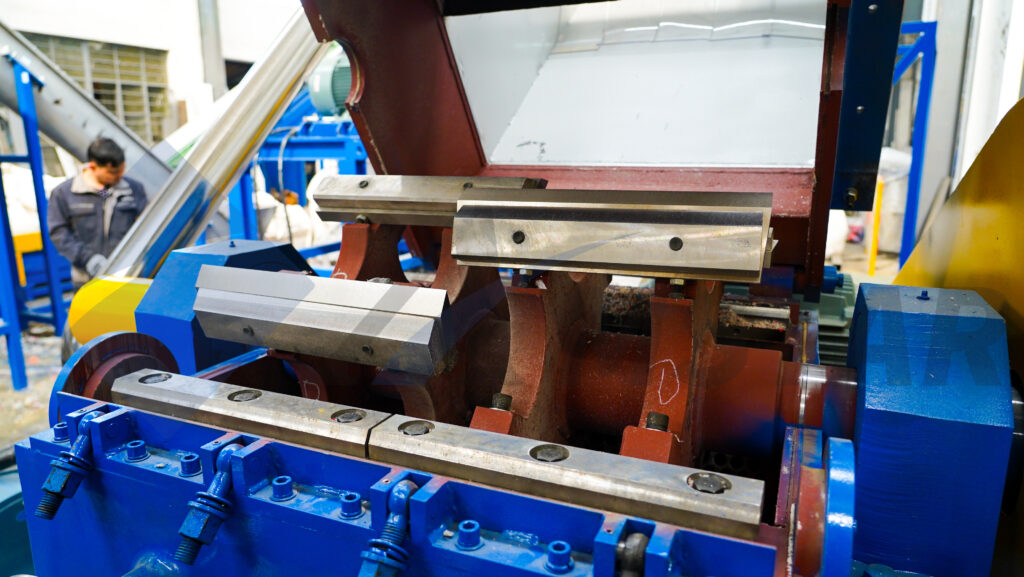

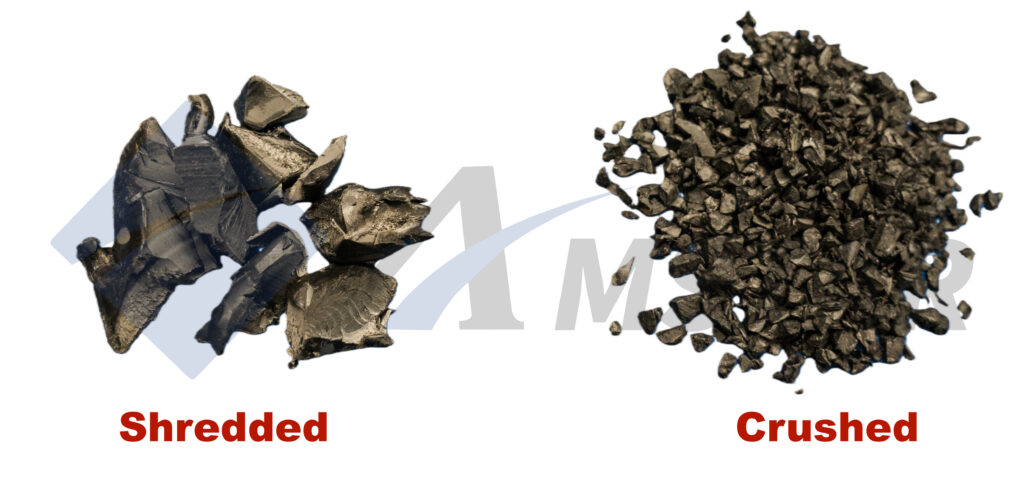

A plastic crusher is a high-speed cutting system consisting of a rotating blade (rotor) and stationary blades (fixed knives), combined with a perforated screen that controls the final flake size. During operation, waste plastics are fed into the cutting chamber, where high-speed shearing forces break down materials into smaller pieces. These uniformly sized flakes (typically 10–18 mm for bottles and 80–120 mm for films) become ideal feedstock for a washing line or pelletizing line.

2. Common Applications

Plastic crushers are widely used in recycling plants, washing lines, and manufacturing facilities for in-house scrap recovery. Typical applications include:

| Material Type | Examples | Output Size (Typical) |

| Rigid Plastics | PET bottles, HDPE drums, PP chairs, ABS/PC parts | 10–18 mm |

| Films & Soft Plastics | PE/PP film, raffia bags, mulch film | 80–120 mm |

| Pipes | HDPE pipe, PVC pipes | 10–20 mm |

| Injection Scrap | Lumps, blocks, purgings, defective products | 10–16 mm |

Uniform flakes produced by the crusher ensure stable washing performance and efficient drying, helping processors achieve higher pelletizing output and better recycled pellet quality.

3. Working Principle (Step-by-Step)

Below is the typical crushing process inside a plastic granulator:

Feeding → Cutting & Shearing → Screening → Uniform Flakes Discharge

Step-by-step explanation:

- Feeding

Waste plastics enter the hopper via manual feeding, a belt conveyor, or a screw feeder.

- Cutting & Shearing

The rotor spins at high speed, pulling material toward the fixed blades for repeated cutting until the pieces become small enough to pass through the screen.

- Screening Control

A perforated screen is mounted beneath the cutting chamber. Only flakes smaller than the screen opening can exit.

- Discharge

Crushed flakes fall into a collection bin or are conveyed directly to the next machine (washer, blower, or silo).

The result is a controlled flake size with consistent shape, minimal dust, and clean edges for efficient washing.

4. Main Components of a Plastic Crusher

| Component | Function |

| Hopper | Receives the waste plastic; can be sound-proof for noise control |

| Rotor / Cutting Chamber | Performs the main cutting action |

| Rotating & Fixed Blades | Shear the plastic through repeated contact |

| Screen Mesh | Determines final flake size |

| Base & Chamber Housing | Provides structural stability |

| Motor & Belt Drive | Delivers rotational power to the rotor |

| Bearings & Safety Covers | Ensure smooth, safe operation |

Blade material and rotor design are two of the most important configuration choices, as they determine crushing efficiency and service life.

5. How to Select the Right Model

When choosing a plastic crusher, consider:

- Material type (film, bottle, rigid, lumps)

- Required capacity (kg/hr)

- Desired flake size

- Noise control requirements

- Dust extraction needs

- Upstream and downstream equipment

For full recycling lines, a crusher is typically positioned after a shredder and before the washing and drying system.

6. Why Choose Amstar

Amstar offers plastic crushers designed for continuous 24/7 recycling operations, with heavy-duty welded structures, high-efficiency cutting rotors, and premium bearings for stable long-term service. Machines are optimized for PET bottle washing lines, PE/PP film recycling lines, and in-house scrap reduction. Each system can be customized for blade configuration, screen size, and capacity.

7. Conclusion

A plastic crusher (plastic granulator) is an essential piece of equipment for any recycling plant. By converting waste plastics into uniform flakes, it enables efficient washing, drying, and pelletizing while reducing transportation and handling costs. Choosing the right machine, configuration, and cutting system will directly impact recycling output, energy consumption, and final pellet quality.

INQUIRIES

To learn more about this product, please send us a message using the form below: