In the plastic recycling industry, one of the biggest challenges is efficiently shredding and crushing bulky or flexible plastic waste. Traditional crushers often struggle when faced with car bumpers, chemical barrels, or tangled film materials — leading to low efficiency and high maintenance downtime.

The Amstar SWHB800 plastic crusher changes that. Designed for strength, precision, and continuous operation, this model can handle a wide range of materials — from thin plastic films and broom fibers to thick-walled car bumpers and chemical drums — all in one powerful machine.

Why Choose the Amstar SWHB800 Plastic Crusher?

1. Superior Crushing Performance

Equipped with a 37 kw full-copper motor and high-strength SKD-11 alloy blades, the SWHB800 provides unmatched cutting power and durability.

The 430 mm rotor diameter delivers exceptional shearing force, ensuring efficient size reduction even for high-strength plastics such as PP, PE, and ABS automotive components.

Compared with conventional machines, the SWHB800 achieves up to 200% higher processing efficiency.

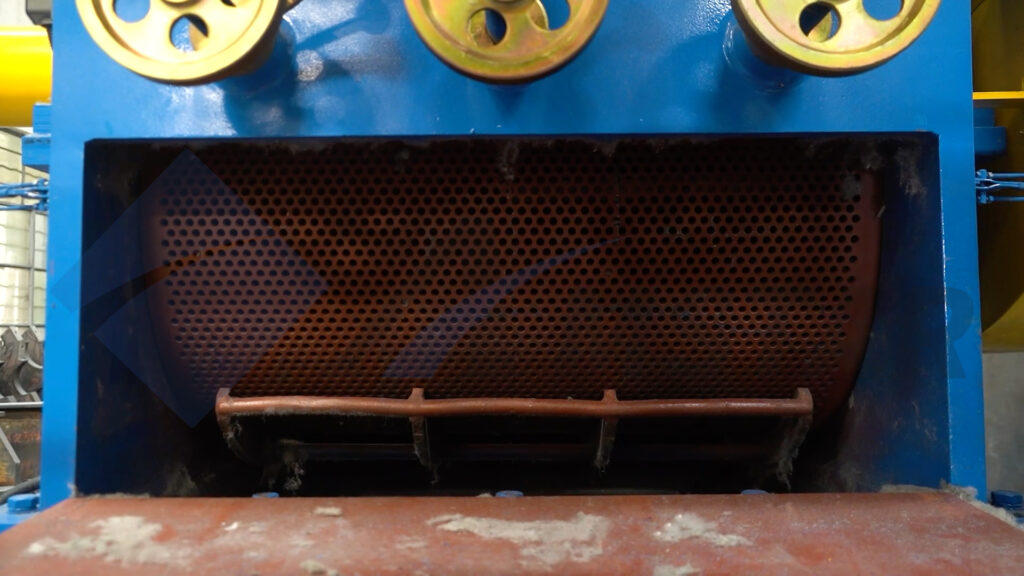

2. Anti-Winding Rotor Design

Flexible materials like plastic film, woven bags, or fibers often cause blade wrapping issues that interrupt production.

Amstar’s SWHB800 adopts a special anti-winding rotor structure, effectively preventing material entanglement and keeping the crusher running smoothly — even under heavy-duty operation.

3. Easy Maintenance, Fast Blade Replacement

Downtime costs money. That’s why the SWHB800 is designed for quick and safe servicing:

- Blades replacement time: less than 30 minutes

- Screen replacement time: around 5 minutes

This user-friendly modular design reduces daily maintenance efforts, maximizing your uptime and overall productivity.

4. Large Feeding Hopper for Big Items

The 1200 × 800 mm feeding opening can directly accommodate entire car bumpers or large chemical barrels without pre-shredding.

This feature not only simplifies the recycling process but also minimizes labor costs and improves efficiency for industrial-scale recycling lines.

5. Intelligent Safety Protection

Operator safety always comes first.

The SWHB800 includes:

- A mechanical interlock that prevents the machine from starting while the chamber is open

- Overload automatic protection, which stops the motor instantly if a jam occurs

These smart safety features ensure both the operator’s security and the machine’s long-term reliability.

Conclusion

If your recycling line is limited by low output, frequent downtime, or material wrapping problems, it’s time to upgrade to a smarter, stronger, and safer solution.

With Amstar’s SWHB800 plastic crusher, you’ll enjoy faster processing, lower maintenance costs, and higher reliability — making it the ideal choice for modern plastic recycling plants.

INQUIRIES

To learn more about this product, please send us a message using the form below: