Application Of Melt Blown Sheets

- Application in the field of air purification: it is used for air purifier, as a sub-high-efficiency and high-efficiency air filter element, and as a coarse and medium-efficiency air filter with large flow rate. It has the advantages of small resistance, large strength, excellent acid and alkali resistance, corrosion resistance, stable efficiency, long service life and low price. There is no short fleece phenomenon in the purified gas.

- Application in the field of medical and health care: made of melt-blown cloth dust mouth breathing resistance is small, not short, dust control efficiency is as high as 99%, widely used in hospitals, food processing, mining and other workplace to dust, prevent bacteria with anti-inflammatory analgesic membrane made of product after special treatment, permeability is good, non-toxic side effects, easy to use, and spun-bonded fabric of SMS composite products are widely used in the production of sanitary products such as surgical clothes.

- Liquid filtration materials and battery diaphragm: polypropylene melt-blown filter cloth used in acidic and alkaline liquid, oil, oil has very excellent performance, such as the battery industry at home and abroad has been regarded as a good membrane material, and has been widely used, not only reduces the cost of battery, simplifies the process, and greatly reduce the weight and volume of the battery.

- Oil absorbent materials and industrial wipes: polypropylene melt spraying cloth made of various oil absorbent materials, oil absorption up to the weight of 14-15 times, widely used in environmental engineering, oil-water separation engineering, in addition, in industrial production, can be used as oil and dust clean materials. These applications give full play to the characteristics of polypropylene and the adsorbability of the ultrafine fiber produced by melting and spraying.

- Thermal materials: the average diameter of fusion-sprayed ultrafine fiber is between 0.5 ~ 5m, the specific surface area is large, and a large number of fine pores are formed in the cloth with high porosity. There is a large amount of air stored in this structure, which can effectively prevent heat loss and has excellent thermal insulation. It is widely used in the production of clothing and various thermal insulation materials. Such as leather jacket, ski shirt, cold clothing, cotton village cloth, with light, warm, moisture absorption, good permeability, no mildew and other advantages.

Description

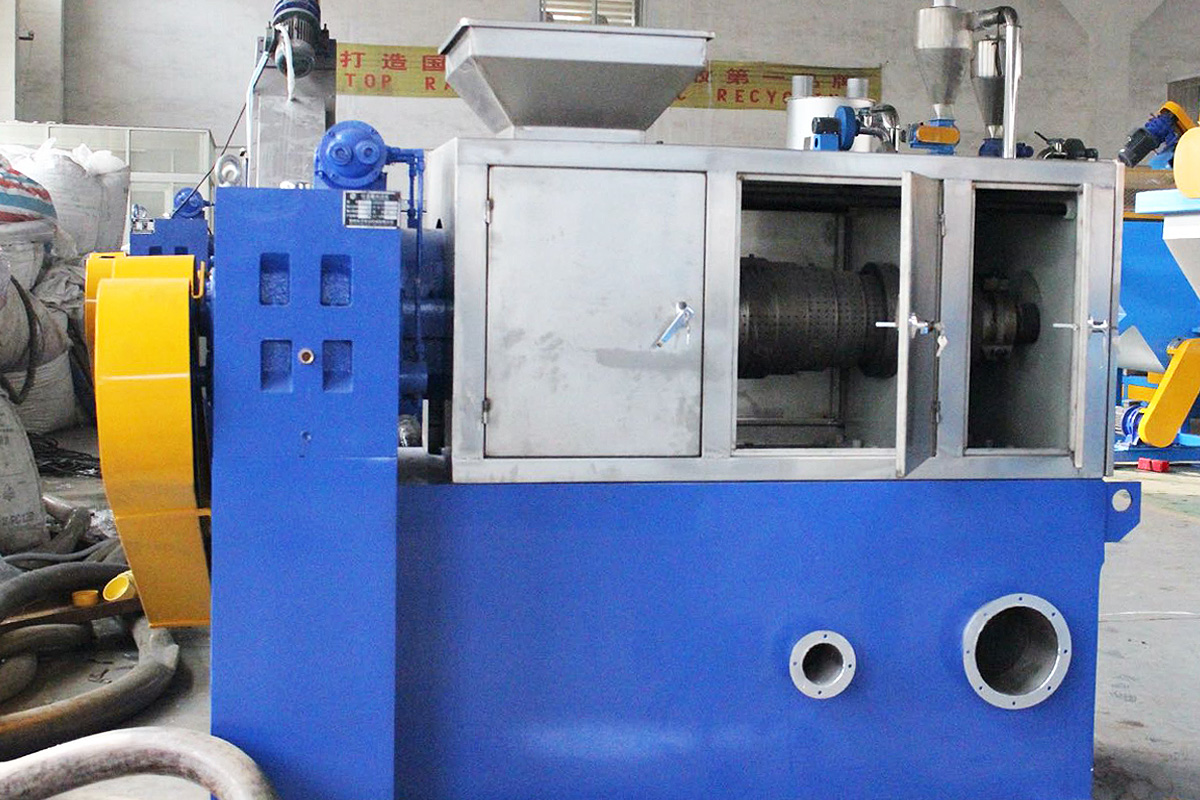

PP melt blown non woven fabric production line/machine is an equipment that used to produce pp melt blown fabric which are widely used both in face mask and medical industry. And the principle of this equipment is as below: Auto Feeder feeds 100% new drawing class polypropylene into Extruder. Then pp materials are melt by heating through Extruder. Roots Blower blows the air into Air Heater and then the heated air will blow the liquid melted polypropylene materials through the Nozzle Heads (with hundreds of small holes in the mold), and finally threaded materials arrive at the Receiving car. Receiving car can be customized. The micro-denier fiber (less than 0.1 denier per filament) is very fine, which only can be produced by melt blown process.It can not be used as nonwoven fibrous raw material alone but the appearance of nonwoven melt blown fabric solves this problem. Nonwoven melt blown fabric is anti-static, breathable, eco-friendly, soft, damp proof, recyclable, easy to shape, water and oil repellence, and antimicrobico. Performance characteristics: PP melt spray nonwoven production line, melting spray production line is based on synthetic high polymer as raw material, after melting spinning wire directly into the net, forming a unique performance of the melting spray nonwovenfabric. Widely used in mask filter materials, insulation filling materials, medical materials, wipe materials.

Models & Specifications

| Raw Material | Polypropylene |

| Fabric Thickness | 2-5mm |

| Production Capacity | 800kg/day |

| Mould Width | 1200mm or custom built |

| Mould Hole Size | 0.2-0.4mm (can bee customized) |

Additional Images

Place An Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.