Among the most common options are single shaft and double shaft shredders, each with distinct advantages suited to different types of materials and operational requirements.

Eddy Current Separators (ECS) are advanced magnetic separation machines designed to remove non-ferrous metals such as aluminum and copper from PET recycling streams.

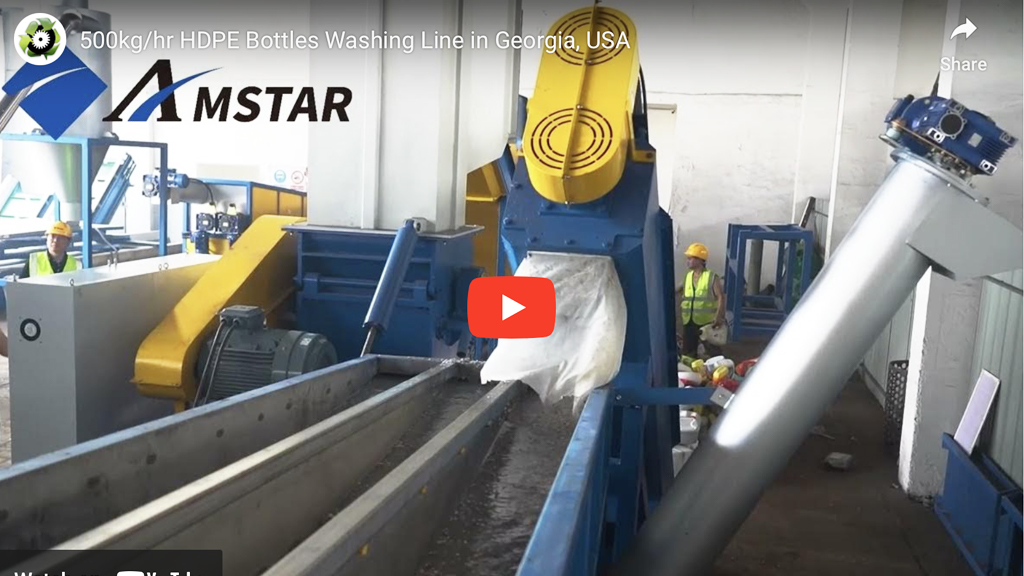

Welcome to our video on the specialized HDPE bottles crushing and washing line designed for our client in Georgia. This plastic recycling system, capable of processing 500 kg per hour, is tailored to handle HDPE bottles efficiently and effectively.

Welcome to our PET Bottle Recycling Line, designed for efficiency and reliability with a capacity of 1 ton per hour. The journey begins with a belt conveyor that transports PET bottles smoothly to the next stage.

Discover the advanced features of our 2000kg/hr HDPE PP Rigid Plastic Crushing and Washing Line, located in Swadlincote, UK.

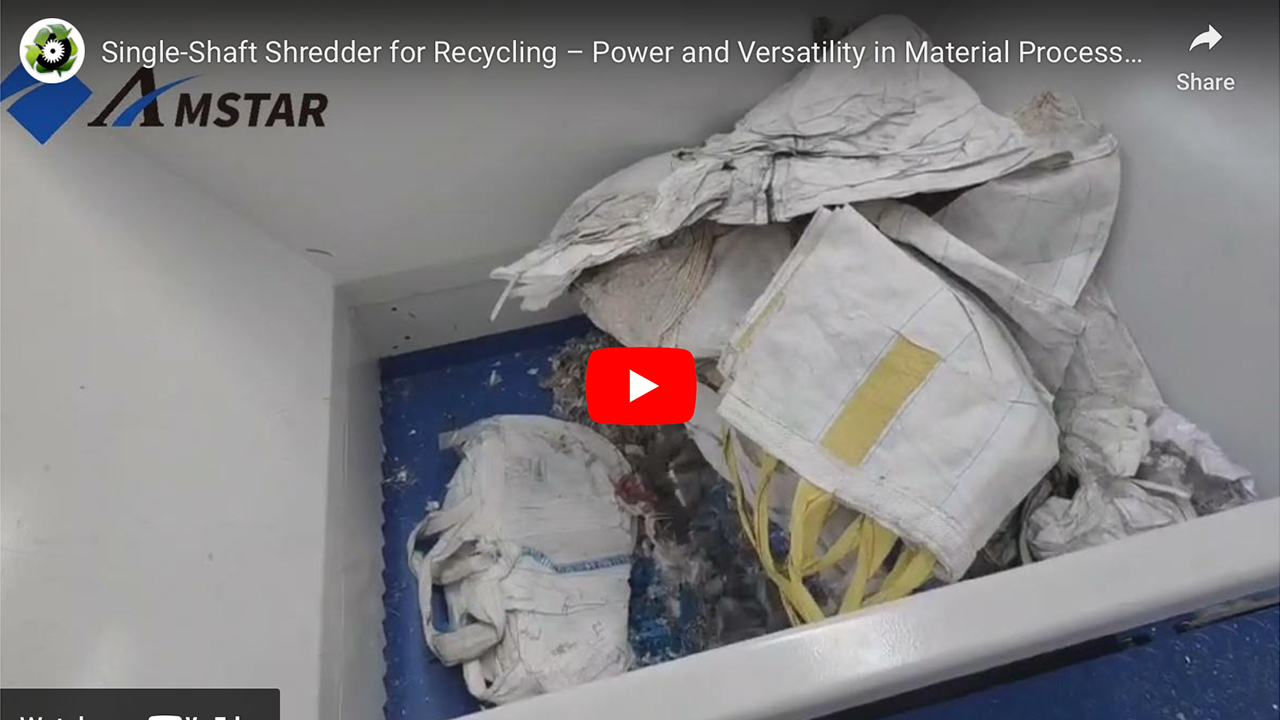

The process begins with shredding, where a single-shaft shredder is used to handle whole bales of PE plastic film with ease. Equipped with a powerful rotor and durable blades, the shredder breaks down bulky materials into uniform strips.

This is a trial run of our PET bottle washing line for a UK customer that been with us for more than 10 years! This 2,000 kg/hr recycling line is the most complex...

Welcome to this video showcasing the power and versatility of our single-shaft shredder. Designed for high-efficiency shredding, this machine can handle a wide range of materials.

Introducing our SJ85 Pelletizing Line, expertly designed to process a variety of materials including PP, PE, HDPE, and ABS regrind plastic.

Here’s the first example: a mix of PET bottles and aluminum cans. Watch as the aluminum cans are repelled and directed into one collection bin, while the PET bottles continue smoothly into a separate bin.